Vanilla—that familiar, warm aroma that has graced kitchens worldwide for centuries—holds a complexity and depth that belies its commonplace status. Behind every drop of vanilla extract lies a fascinating scientific journey, one that transforms humble green pods into the aromatic elixir revered by chefs and home cooks alike. This article delves into the chemistry and methodology behind making vanilla extract, comparing time-honored traditional processes with cutting-edge modern techniques.

Understanding Vanilla's Chemical Composition From The Vanilla Bean

Before examining extraction methods, we must first understand what makes pure vanilla so distinctive. The vanilla orchid (Vanilla planifolia, primarily) produces seed pods containing over 250 identified compounds, with vanillin being the principal flavor component. However, it's the synergistic effect of all these compounds—including vanillic acid, p-hydroxybenzaldehyde, p-hydroxybenzoic acid, and various aromatic alcohols—that creates vanilla's complex profile.

In fresh green vanilla pods, these flavor compounds exist primarily as glycosides—molecules bound to sugars that render them non-volatile and flavorless. The art of vanilla processing lies in liberating these compounds from their glycosidic bonds to create the aromatic profile we recognize as vanilla.

Traditional Extraction Pure Vanilla Methods

The Curing Process: Nature's First Extraction Of The Vanilla Bean

Traditional pure vanilla production begins with curing—a process that has remained largely unchanged for centuries and represents the first crucial extraction phase.

Killing The Vanilla Bean To Making Vanilla EXtract

The biochemical transformation of vanilla begins with the "killing" stage, where enzymatic activity within the pod is initiated. Traditional methods include:

- Sun killing: The vanilla beans are laid in the sun during the day and wrapped in cloth at night to "sweat." This process may take 7-10 days.

- Hot water scalding: Pods are immersed in 65-70°C water for 2-3 minutes, which quickly stops vegetative growth and initiates enzymatic reactions.

- Oven killing: Beans are placed in ovens at controlled temperatures around 60°C, a method that offers greater consistency but may affect flavor nuances.

During this phase, the cellular structure of the pod is disrupted, allowing enzymes to come into contact with the glycosides. The primary enzyme, β-glucosidase, begins cleaving the sugar-vanillin bonds, releasing free vanillin and other aroma compounds.

Sweating and Drying Pure Vanilla

Following killing, beans undergo alternating periods of sweating (wrapping beans to maintain high humidity and temperature) and sun-drying. This process may continue for 3-6 months, during which time:

- Enzymatic hydrolysis releases flavor compounds

- Oxidation and other chemical reactions create additional aroma compounds

- Moisture content gradually reduces from about 85% to 25-30%

- The characteristic dark brown color develops as phenolic compounds oxidize

- Complex Maillard reactions occur, forming new flavor molecules

The microbiological aspects of traditional curing cannot be overlooked. Research has identified specific bacteria and fungi that contribute to vanilla's flavor development during this phase. These microorganisms produce enzymes that catalyze reactions impossible through purely chemical means, creating subtle flavor notes that distinguish traditionally cured vanilla.

Alcohol Extraction: The Classic Method

Once cured, vanilla pods are traditionally extracted using ethanol—a technique dating back centuries. The process typically involves:

- Chopping or grinding cured vanilla beans

- Immersion in ethanol (typically 35-50% concentration)

- Maceration for several weeks to months, with occasional agitation

- Filtration to remove solids

The science behind alcohol extraction is straightforward but elegant. Ethanol's molecular structure features both hydrophilic (water-loving) and hydrophobic (water-repelling) regions, making it an ideal solvent for both polar compounds like vanillin glycosides and non-polar aromatic compounds. As the beans macerate, the alcohol penetrates cell structures and dissolves the flavor compounds.

Time plays a crucial role in traditional extraction. During long maceration periods, slow chemical reactions continue to occur within the solution, leading to greater complexity in the final extract. Studies comparing quick extractions to those aged for months demonstrate measurable differences in compound profiles, with longer extractions showing higher concentrations of certain esters and phenolic derivatives.

The ethanol concentration significantly impacts extraction efficiency and flavor profile. Higher alcohol content (>60%) extracts more of the resinous, less water-soluble compounds but may leave behind water-soluble flavors. Lower concentrations (<35%) may fail to extract enough of the essential oils but preserve more of the delicate top notes. The industry standard of 35-50% ethanol represents a carefully calibrated balance point.

Modern Extraction Techniques Of The Vanilla Bean

Contemporary food science has developed alternative extraction methods that aim to increase efficiency, consistency, and sometimes yield novel flavor profiles.

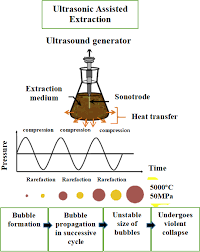

The Vanilla Bean Ultrasonic-Assisted Extraction (UAE)

Ultrasonic extraction employs high-frequency sound waves (>20 kHz) to create microscopic bubbles in the solvent that violently collapse—a phenomenon known as cavitation. This process:

- Creates localized areas of extreme temperature and pressure

- Disrupts cell walls mechanically

- Accelerates diffusion of compounds into the solvent

- Reduces extraction time from weeks to hours

Research published in the Journal of Food Science demonstrated that ultrasonic-assisted extraction could achieve comparable vanillin yields to traditional methods in just 4-6 hours versus several weeks. However, some studies suggest that while major compounds are efficiently extracted, some of the subtle background notes may be altered or lost.

The technology allows precise control over parameters like wave frequency, amplitude, and treatment time, enabling processors to target specific compound ranges. This has led to the development of specialized vanilla extracts with tailored flavor profiles impossible to achieve through traditional methods.

Supercritical Fluid Extraction (SFE)

Perhaps the most technologically advanced extraction method utilizes supercritical carbon dioxide (SC-CO₂)—CO₂ maintained above its critical temperature and pressure (31.1°C and 73.8 bar), where it exhibits properties of both a liquid and a gas.

In this supercritical state, CO₂:

- Flows like a gas but dissolves compounds like a liquid

- Can penetrate deep into plant material

- Has selectivity that changes with minor adjustments to temperature and pressure

- Leaves no solvent residue, as the CO₂ returns to gas form when pressure is released

SFE offers remarkable precision in targeting specific vanilla compounds. By adjusting operating parameters, technicians can create extracts with higher concentrations of certain desired compounds while minimizing others. For instance, increasing pressure from 100 to 300 bar progressively extracts different vanilloid compounds, allowing for customized flavor profiles.

The environmental advantages are significant—no organic solvent waste and reduced energy consumption compared to distillation methods. However, the high initial capital investment and technical complexity have limited widespread adoption.

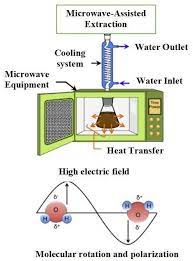

The Vanilla Bean Microwave-Assisted Extraction (MAE)

Microwave technology provides another modern approach, using electromagnetic energy to heat moisture within plant cells, creating internal pressure that ruptures cell walls and releases compounds quickly.

MAE offers:

- Extremely rapid extraction (minutes versus weeks)

- Reduced solvent usage

- Relatively low operating temperatures that preserve heat-sensitive compounds

Studies comparing MAE to traditional methods have found it can achieve similar vanillin extraction efficiency in dramatically shortened timeframes. However, research published in Food Chemistry noted significant differences in the aromatic profile of MAE extracts compared to conventional ones, with some compounds found in higher concentrations and others diminished.

Enzyme-Assisted Extraction

Biotechnology has enabled extraction methods that mimic and accelerate natural enzymatic processes. By introducing specific enzymes like cellulase, hemicellulase, and β-glucosidase to vanilla preparations, processors can:

- Break down cell walls more efficiently

- Release bound glycosides rapidly

- Increase overall yield of flavor compounds

This method operates at moderate temperatures (30-50°C) that preserve delicate compounds while accelerating the reactions that would naturally occur during traditional curing. Research from the University of Copenhagen demonstrated that enzyme pre-treatment followed by conventional extraction increased vanillin yield by up to 24% compared to conventional methods alone.

Comparative Analysis Of The Vanilla Bean Extraction: Traditional vs. Modern Methods

Flavor Profile Differences

Chemical analysis using gas chromatography-mass spectrometry (GC-MS) reveals significant differences in the flavor profiles produced by different extraction methods:

- Traditional alcohol extraction produces the broadest spectrum of compounds, including trace compounds that develop during long maceration periods. It maintains an optimal balance of "top notes" (volatile compounds that hit immediately) and "base notes" (less volatile compounds that provide lingering flavor).

- Ultrasonic extraction efficiently pulls major compounds but may alter the ratios of some sensitive aromatics, resulting in a profile described by sensory panels as "brighter" but sometimes lacking depth.

- Supercritical CO₂ extraction excels at capturing essential oils and lipophilic compounds but may miss some of the water-soluble components unless modified with co-solvents. The resulting extract often has pronounced "top notes" but requires careful parameter tuning to capture full complexity.

- Microwave extraction tends to produce higher concentrations of certain heat-generated compounds while potentially degrading others, creating distinctive profiles that some describe as having "cooked" notes.

Efficiency and Sustainability Considerations

Modern methods dramatically outpace traditional techniques in terms of time efficiency:

- Traditional alcohol extraction: 3-8 weeks

- Ultrasonic-assisted extraction: 1-6 hours

- Supercritical fluid extraction: 30-90 minutes

- Microwave-assisted extraction: 5-30 minutes

The economic implications are substantial, particularly in terms of labor costs and production capacity. However, energy requirements vary considerably; SFE requires significant energy to maintain pressure, while traditional methods have minimal ongoing energy needs but greater labor input.

From a sustainability perspective, modern methods typically use less solvent. Traditional extraction may use ethanol-to-bean ratios of 10:1 or higher, while UAE and MAE can achieve similar extraction with ratios of 5:1 or less. SFE uses no permanent solvent, as the CO₂ is recycled within the system.

Commercial Applications and Market Trends Of Pure Vanilla

The vanilla extract market has become increasingly segmented, with different extraction technologies serving different product categories:

- Culinary Applications: Traditional alcohol extractions still dominate premium baking and dessert applications, where full flavor complexity is paramount. However, consistent, cost-effective extracts from modern methods are gaining ground in mass-market products.

- Fragrance Industry: SFE has made significant inroads in perfumery, where its ability to capture volatile "top notes" while leaving behind undesirable compounds is highly valued.

- Pharmaceutical and Nutraceutical Applications: The precision of modern techniques has enabled isolating specific vanilla compounds with potential health benefits. Vanillin and certain vanilla extract fractions have demonstrated antioxidant and antimicrobial properties in research settings.

Industry analysts report that while traditional extracts command premium prices in specialty markets, the efficiency of modern methods is steadily decreasing the overall cost of vanilla flavoring, expanding its use in new product categories.

The Future of Pure Vanilla Extraction

Emerging technologies continue to push the boundaries of vanilla extraction science:

- Pulsed Electric Field (PEF) Processing: By applying short pulses of high voltage to plant materials, cell membranes can be permeabilized without heating, potentially preserving delicate compounds while accelerating extraction.

- Nano-encapsulation: Research is exploring methods to encapsulate vanilla extracts in nano-sized carriers that protect volatile compounds and allow for controlled release.

- Bioreactor Technology: Rather than extracting compounds from vanilla beans, some companies are developing bioreactors where engineered microorganisms produce vanillin and related compounds through fermentation.

These innovations suggest that the science of vanilla extraction will continue to evolve, potentially offering new flavor experiences and applications beyond what traditional methods can provide.

Conclusion

The journey from traditional to modern vanilla extraction methods represents more than just technological progress—it reflects our changing relationship with flavor itself. While traditional methods remain unsurpassed for producing the full complexity that vanilla aficionados cherish, modern techniques offer precision, efficiency, and novel profiles that expand vanilla's applications.

Perhaps the most interesting development is not the replacement of traditional methods but their complementary relationship with new technologies. Many premium pure vanilla producers now employ hybrid approaches—using traditional curing followed by modern extraction methods, or blending extracts from different processes to achieve specific flavor profiles impossible through any single method.

As our understanding of vanilla's chemistry deepens and extraction technology advances, we can expect this humble spice to continue revealing new dimensions of flavor—a remarkable testament to how science can enhance rather than diminish the magic of natural ingredients.

If you are looking source pure vanilla extract with any varieties of vanilla derivatives. We are, Agro Vanilla is the best vanilla supplier for your needs